Dimac Starwrap R25

Dimac machine created to form complete cartons from flat blanks.

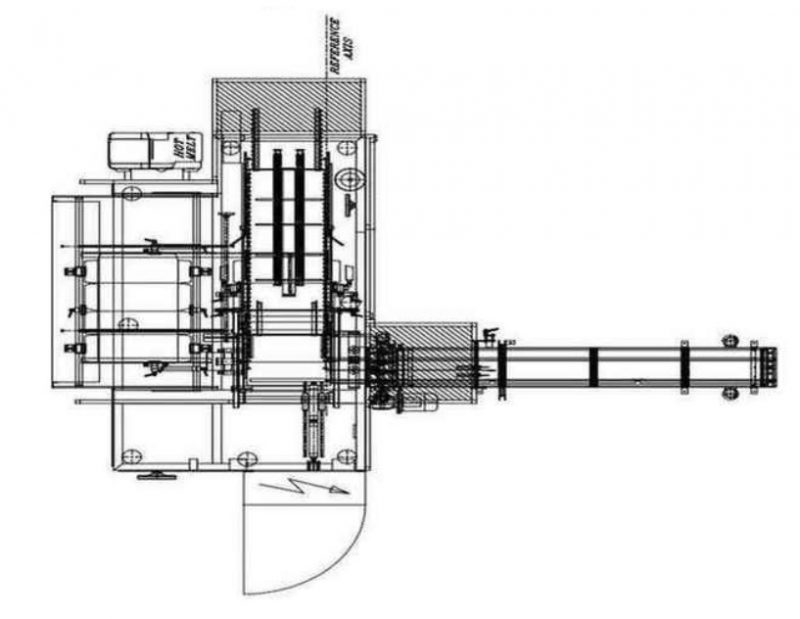

The Starwrap R25 is a wrap around case packer with input and output placed on two levels with a speed of 25 PPM. Cartons are formed when the product is lowered through a plate controlled by a mechanical cam. The Starwrap R25 is available in the in-line or 90° versions.

B.I. SEPARATION

Alternated separation system to create the required configuration. The system is composed of a metal conveyor mesh that guarantees the execution of the configuration required through a start/stop system. An upper pneumatic press stabilizes the product in the post-separation stage. Suitable for customers with many format changes thanks to its flexibility and precision. Adjustable through a panel and simple manual operations.

CARTON MAGAZINE

The carton is picked up from the feeder by an arm with suction caps equipped with vacuum generators. The carton feeder has a high capacity and is easy to adjust. cartons are placed inside guides and transported below the product so that, when the product is pushed by the crossbar, it is placed perfectly above the carton.

CARTON FORMATION SYSTEM

Once the products are taken from the feeder and shifted, the cartons are transferred to the “wrap-around” area. The plate is controlled by the cam movement and enables their descent creating the first folding stage. An alternated-progress compartment conveyor transfers the cartons to the next stage. The following stages are – folding of the inner flaps, distribution of the hot-melt glue, folding of the upper part and losing of the external flaps.

STAWRAP R25P

Cartoning machine with 90° feed

This type of load enables the processing of products at low speed or with irregular shapes. Loading can be set as single or multiple-lane according to the speed and configuration required. The system will take the product inside the machine in positive form, where a programmable pusher transfers it in the Carton formation area.

SPECIFICATIONS

| Performance | |

| Capacity/Speed (Packs Per Min) | 25 PPM |

| Format Options | Wraparound |

AVAILABLE OPTIONS

| Air Conditioning (Control Panel) | Automatic Film Splicing |

| Can Labelling Orientation | Case Turner on Board |

| Film Cutter Extractible | Infeed Side Transfer Conveyor |

| Remote Servicing | Rockwell PLC & HMI |

| Servo Automatic Change Over | Stacker |

| Stain Less Steel Execution | UL or CSA Compliancy |

ADDITIONAL RESOURCES

DIMAC STARWRAP SERIES (English & Italian) Brochure