Dimac Laser

LASER machines are sealing bar style shrink bundling machines with the ability to run neutral film in the following formats at a max rate of 20 PPM.

MACHINE MODELS

F Film Only

P Pad & Film

T Tray and Film

TX Tray Only

ALTERNATED SEPARATION

Simple alternated separation system for the majority of the configurations required by the market. The system works by creating a gap between the products that are being fed and the preset format. Operators can manage the system easily thanks to simple manual and panel adjustments. It is also possible to adjust feeding guides using a counter wheel (optional) to speed up format changing operations.

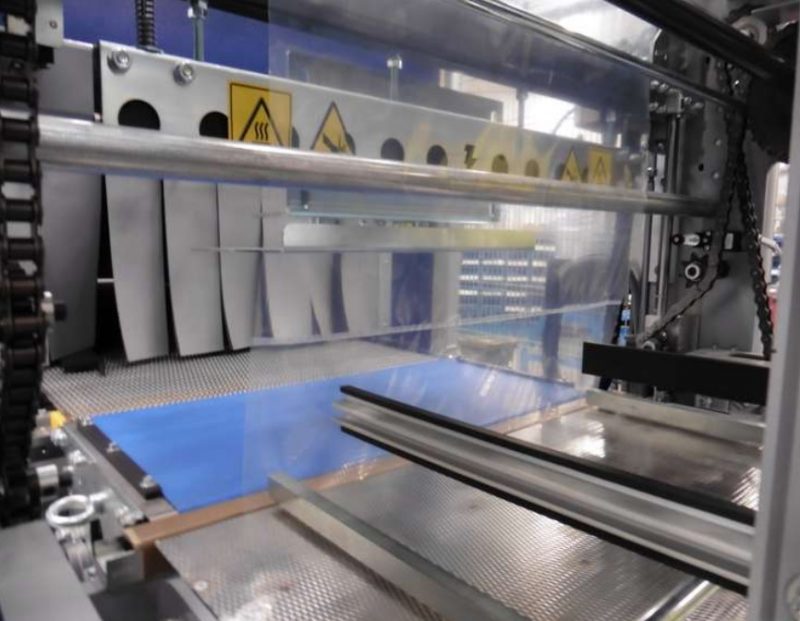

SEALER

The sealed film coming from the upper and lower reels is stretched vertically. As the product moves forward, the film unrolls and wraps the processed product. The upper press is located after the sealing unit and keeps the product stable while the sealing bar comes down and the film is cut so as to completely wrap the product.

HEAT SHRINK TUNNEL

The tunnel is equipped with external regulation to optimise air flow according to the different configurations. Conveyor voltage is maintained constant by a counterweight in the final part of the tunnel.

SPECIFICATIONS

| Performance | |

| Capacity/Speed (Packs Per Min) | 20 PPM |

| Format Options | Film Only, Pad+Film, Tray+Film, Tray Only |

KEY FEATURES

Automatic Film Splicer Option

B&R PLC & HMI

Cut Film Conveyor

Double Film Roller

Easy Film (Film Rolls Positioned Outside From The Machine Frame

Elau Schneider PLC & HMI

Ergonomic Carton Magazine

AVAILABLE OPTIONS

| Air Conditioning (Control Panel) | Automatic Film Splicing |

| Can Labelling Orientation | Case Turner on Board |

| Film Cutter Extractible | Infeed Side Transfer Conveyor |

| Remote Servicing | Rockwell PLC & HMI |

| Servo Automatic Change Over | Stacker |

| Stain Less Steel Execution | UL or CSA Compliancy |