Prasmatic MSW

AUTOMATIC SHRINK WRAPPING MSW SERIES

MSW is the series of PRASMATIC medium-speed automatic shrink film wrapping machines mainly dedicated to the food and beverage industries, where the primary requirement of high productivity is combined with the request for high reliability and flexibility.

The new 7″ color touchscreen makes it easy to set up the correct parameters for wrapping each of your loads. You control pre-stretch, containment force, rotation speed, roping and banding at 9 levels on each load.

Lock in the best wrap settings for up to six completely unique load configurations and save them. Your operator can then recall the appropriate program over and over with a touch of the control panel. You can name each program to ensure that your operators always select the correct standard.

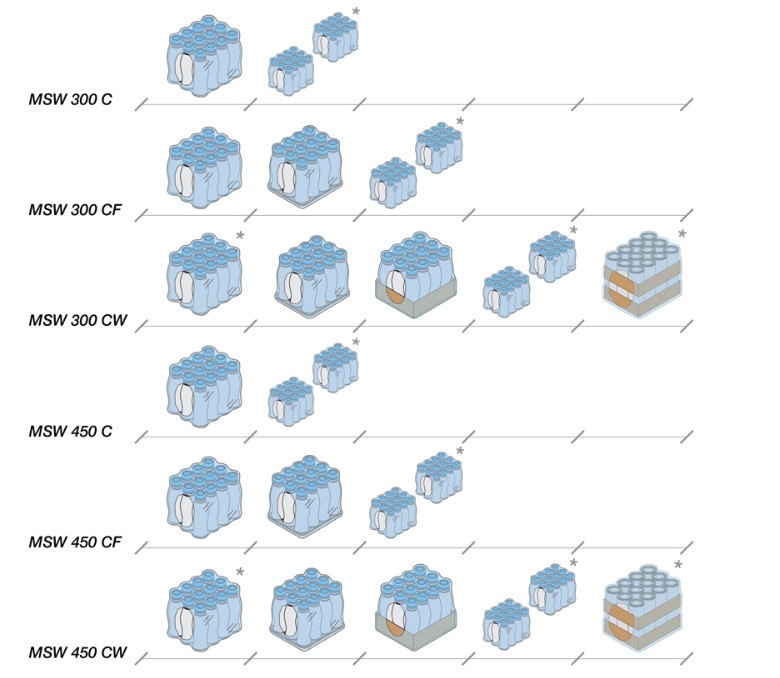

Type of packaging

OPERATING SOLUTIONS

MODELS

AUTOMATIC MULTILANE DIVIDER

This device can be set up at the machine infeed to feed and distribute single products or product packages coming from a single-row belt into more than one row. The divider comes in various models and configurations based on line production speed and product type, it is particularly suitable for products with an irregular shape.

PRESS SEPARATION

The press separation system is suitable for medium/low speed. The product used to create the format is separated by the combined action of the press and the bottom conveyor belt. This solution ensures the maximum simplicity in terms of function and adjustment during the format change operations.

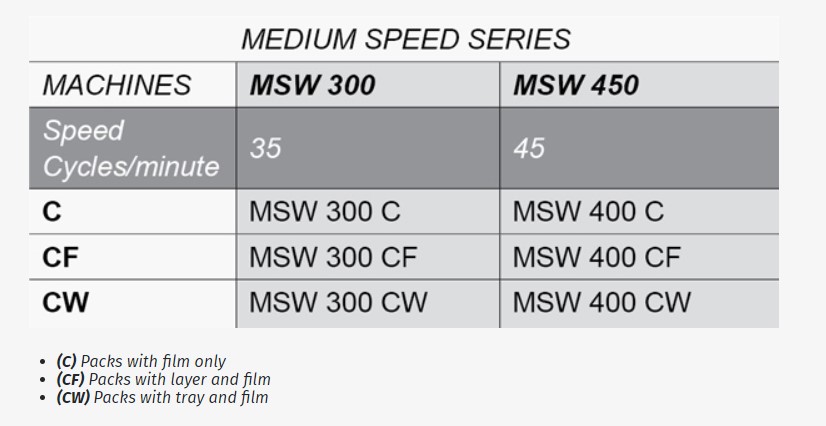

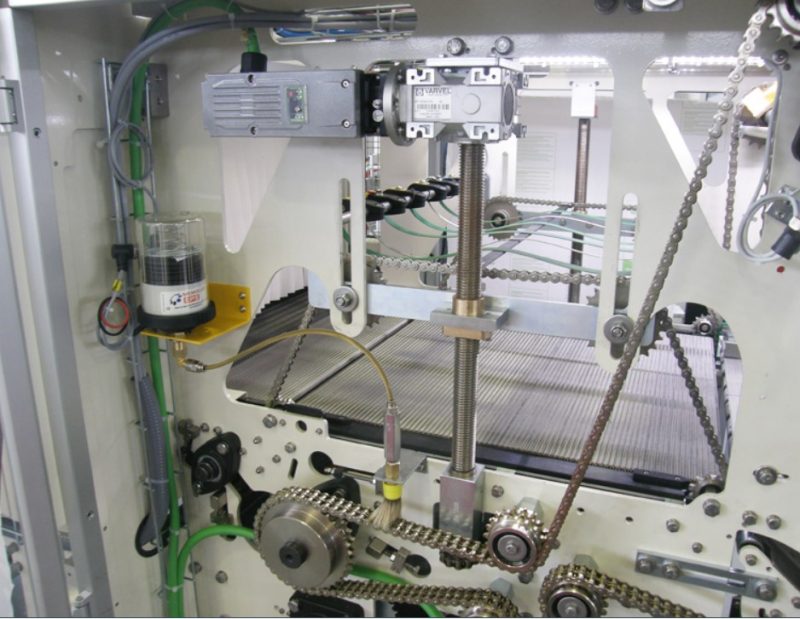

ELECTRONIC PRODUCT SEPARATION

Continuous separation system with electronic control for medium and high speed. Product separation is carried out through a double pair of teeth, with infeed between the products from the bottom. It is very easy to make adjustments during format changes to change the product size.

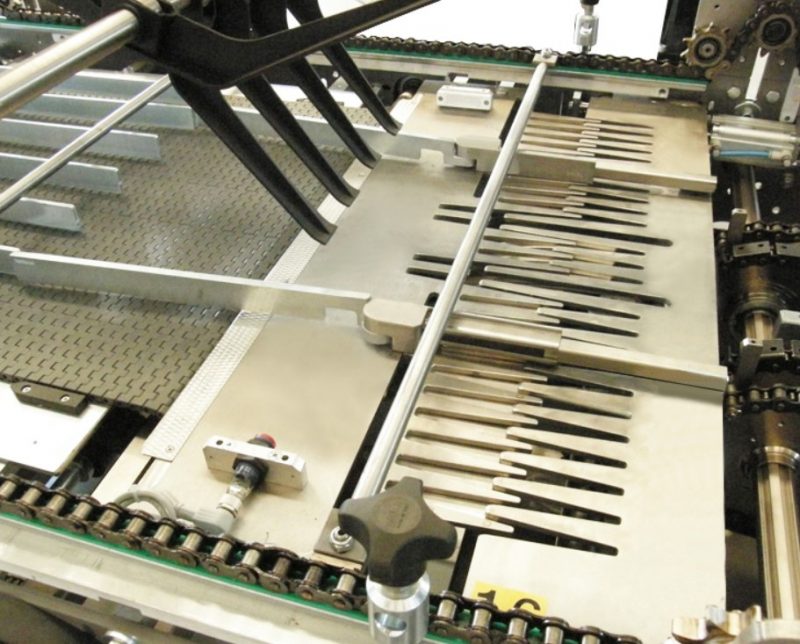

RETRACTABLE COLLATING PLATE

This solution offers high flexibility for the range of formats that can be produced, it also offers an excellent compromise when switching from tray packaging to packs with heat-shrink film only, and vice versa. The pneumatically-actuated surface offers the possibility of producing trays with high edges, it is particularly suited for the production of full height trays.

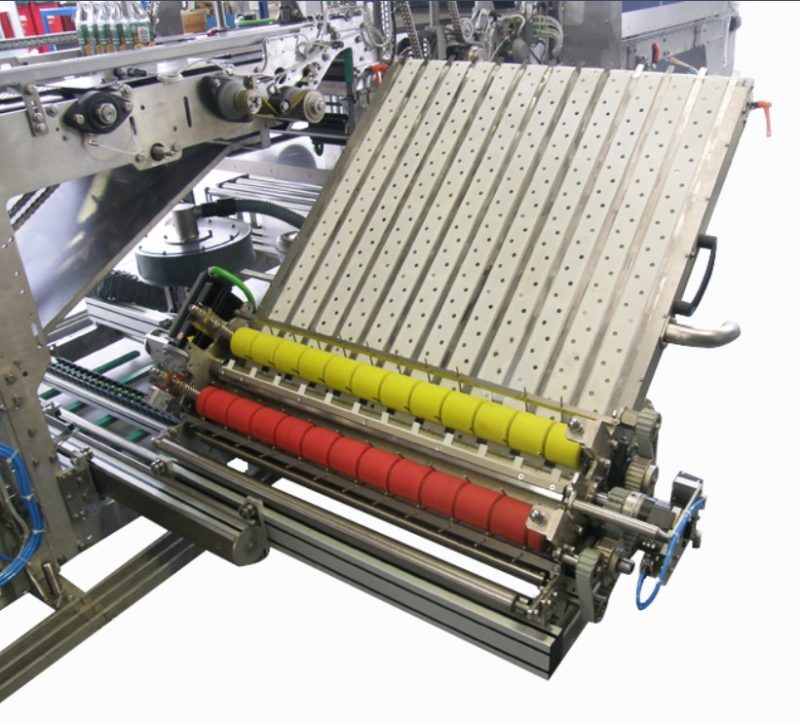

FILM REELS

Various film reel positioning solutions are available, the ergonomics are particularly well-designed. Better access for format change operations and reel sealing means excellent man-machine interaction. The external reels option also offers automatic reel-change. AUTOMATIC REEL CHANGE The system seals and cuts the film in a fully-automated fashion without any operator intervention, this option makes it possible to continue without stopping film unwinding and the production cycle. The reel configuration is set up by the operator, through simple manual procedures.

REMOVABLE FILM UNIT

The system offers easy access the film unit, for quick and efficient maintenance. This application is particularly suited for liquid product sectors, such as dairy and beverage, where the primary packaging may break, possibly soiling the film

AUTOMATIC FORMAT CHANGE

For models with automatic format change, switching to the new format is carried out electronically through brushless motors, in most cases there is no need for tools or for the machine to be manned by the operator. Format change operations are carried out simply from the operator panel.

STACKERS

The role of the stacker unit is to stack two or more layers of product, the unit can be configured differently based on the type of product or the packaging solution. Thanks to its reduced dimensions or its mechanism, it can be installed without increasing the footprint of the base machine.

SPECIFICATIONS

| Performance | |

| Capacity/Speed (Packs Per Min) | Max 35 to 45 PPM |

| Format Options | Film Only, Tray Only, Pad & Film, Tray & Film, Wraparound |

AVAILABLE OPTIONS

| Air Conditioning (Control Panel) | Automatic Film Splicing |

| Can Labelling Orientation | Case Turner on Board |

| Film Cutter Extractible | Infeed Side Transfer Conveyor |

| Remote Servicing | Rockwell PLC & HMI |

| Servo Automatic Change Over | Stacker |

| Stain Less Steel Execution | UL or CSA Compliancy |

ADDITIONAL RESOURCES

PRASMATIC MSW SERIES Brochure – PDF