ROTOTECH 708 CW

Our Rototech CW with CUBE Technology will reduce your film usage by 30% to 55%, improve your load containment and reduce potential product damage. This ensures that your product reaches your customer in “as-made” condition by maintaining proper wrapping standards.

The Heavy Duty Cut, Clamp and Weld System can save you an average of two (2) minutes of labor per load. For the average customer, this translates to $60,000 in labor savings!

Our PVS roll carriage employs a dual motor pre-stretch system that provides the ability to pre-stretch film from 150% up to 400% using two independent, variable AC motors.

The intuitive icon-driven touchscreen makes it easy to set up the correct parameters for wrapping each of your loads. You control containment force, rotation speed, roping and banding at nine (9) levels on each load.

With CUBE Technology!

Our innovative CUBE Technology offered on this machine combines the following four (4) key factors to successfully wrap loads & ensure that they reach your customer in “as-made” condition by maintaining proper wrapping standards.

- Multi-Level Variable Pre-Stretch ensures the best film economy & delivers 30-55% film savings.

- Multi-Level Variable Containment Force delivers optimal containment force at each level of the load.

- Pro-Active Corner Compensation enables you to wrap any load securely without corner damage or repetitive film breaks.

- Strategic Film Placement allows you to place film exactly where it has the most impact on load stability and containment.

AUTOMATIC FILM CUT, CLAMP AND SPREADING SYSTEM (CS)

The cut, clamp and spreading system ensures a perfect adherence of the final round of film on the wrapped product. The new aluminum clamp controlled by a pneumatic cylinder holds the film clearly and without slippage during cutting.

R-CONNECT READY

R-Connect, available for this machine is our latest innovation was developed to provide usage and performance data via the cloud, enabling you to meet Industry 4.0 demands by putting performance monitoring & optimization at your fingertips. Utilization drastically reduces downtime by giving you informational transparency, allowing you to connect with your machines remotely to investigate alarms, adjust parameters, & respond promptly. This Industry 4.0 innovation empowers you with actionable insight to continuously improve performance, cost savings, & automation.

COLOR TOUCH SCREEN

The control panel has been newly designed, adopting it to a touch screen. Thanks to the large 7″ color touch screen this new panel allows you to create programs simply and immediately. It is supplied with more memory to record up to 12 different programs (6+6 with Multilevel Control).

PVS CARRIAGE

The PVS Carriage with powered stretch system controlled by two independent motors. Stretch ratio adjustable from panel board from 150% up to 400%. Force to the load controlled by patented electronic device and adjustable from panel board.

HORIZONTAL ROTATING EXTENDABLE ARM

A robust structure made of steel plate .25 inch think forms the backbone of this powerful rotating horizontal arm. Robopac has gone further and has produced the first adjustable rotating arm machine. It is now possible to adjust the length of the rotating arm to its maximum horizontal movement, allowing the user to wrap products with maximum dimensions 55″ x 55″. Wrapping dimensions of the Rotary can also be reduced by simply adjusting the minimum length of the horizontal rotating arm. This allows wrapping products down to a size of 47″ x 47″.

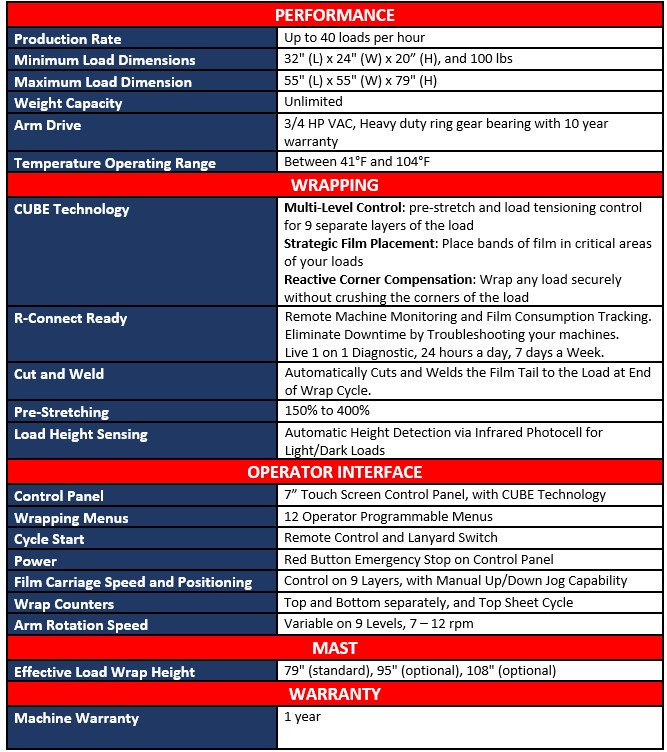

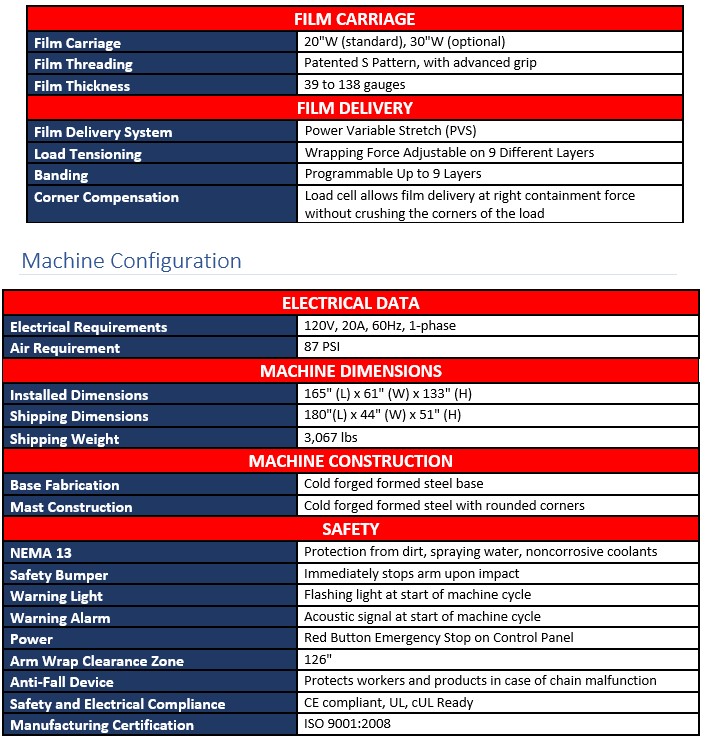

SPECIFICATIONS

ADDITIONAL RESOURCES

ROTOTECH 708 CW Brochure – PDF